05 Feb 2026

Summary: Rainfall and soil conditions directly impact cement strength in northeastern states like Assam and Meghalaya. The blog discusses how rain, water quality, and soft soils affect cement curing and performance. We will also guide you to choose the right cement for monsoon climates that improves durability.

Construction in north-east India has always been challenging. The high humidity, sudden rainfall, sloping land, soft soils, and seismic activity can influence the performance of the structure. Therefore, when it comes to choosing the best cement for concrete construction, it is important to consider the soil type and rainfall in your area.

Not every cement reacts the same way to water, moisture, or curing delays. If you choose the wrong grade of cement for a monsoon climate or handle the right one poorly, it can impact the integrity of structures. Many home and building owners often complain about cracks and water seepage after a few years or even months.

This guide explains how cement performance changes with weather and site conditions, and how to make informed choices for monsoon-heavy, hilly regions.

Why Cement Performance Changes With Climate

Concrete strength usually depends on the chemical reaction between cement and water, called hydration. During the mixing and early placement stage, if the amount of water is not enough, the cement particles can’t fully react. Hydration stops midway, which results in lower strength, poor bonding, and increased brittleness.

Too much water, added at the mixing stage or introduced before initial setting, increases the distance between cement particles, forming capillary pores as the water later evaporates. These pores reduce density, lower compressive strength, and make concrete more permeable to moisture and chemicals.

In high-rainfall regions, this becomes a major challenge during batching, placing, and early setting. Excess rainwater can unintentionally increase the water–cement ratio, directly affecting the final strength and durability of concrete.

How Rainfall and Water Quality Affect Concrete Strength in Assam

Though rainwater may seem harmless, it’s chemically different. Lab tests show that rainwater with a pH around 5.8 can cut 28-day compressive strength by about 16.3% versus neutral (pH 7.0) water. However, less compressive strength means more permeability. This also increases the chance of surface defects, such as scaling and dusting.

When workers increase the unit water content due to poor control or sudden rain, it can increase porosity and bleeding. Here are a few common practices when using cement in a monsoon climate:

During Mixing

When water enters aggregates or mixes drums, it changes the water–cement ratio. Even a tiny amount of water can dilute the cement and weaken the internal bond. This impacts the strength of the concrete.

Not just that, sometimes contractors leave the aggregates uncovered at night. In high-rainfall regions, they often absorb moisture overnight, which then adds hidden water to the mix.

During Pouring

Fresh concrete is most vulnerable during pouring. This is one of the primary reasons why many construction projects stay on hold during the monsoon. The rain falling directly on newly placed concrete washes away cement paste from the surface. This process is known as laitance formation.

The top layer becomes weaker and has a poor surface finish. This also causes problems in the long term, such as dusting, scaling, and early wear. In the worst-case scenario, the surface may appear finished but lacks sufficient strength.

Site teams usually rely on a few practical controls to limit damage during pouring, including:

- Cover freshly poured concrete with temporary tarpaulins or sheds.

- Postpone casting during heavy or continuous rainfall.

- Place plastic sheets immediately after levelling and finishing.

During Curing

Curing is essential for the concrete to gain most of its strength. The moisture level should be controlled at this stage. Thus, continuous curing is important. Keeping concrete evenly moist for at least 7 to 14 days allows the cement to react properly without interruption. Methods like pond curing, regular water spraying, or using curing compounds help maintain this moisture.

However, sudden rain influences the drying of cement, leading to:

- Lower compressive strength,

- Increased permeability, and

- Reduced service life.

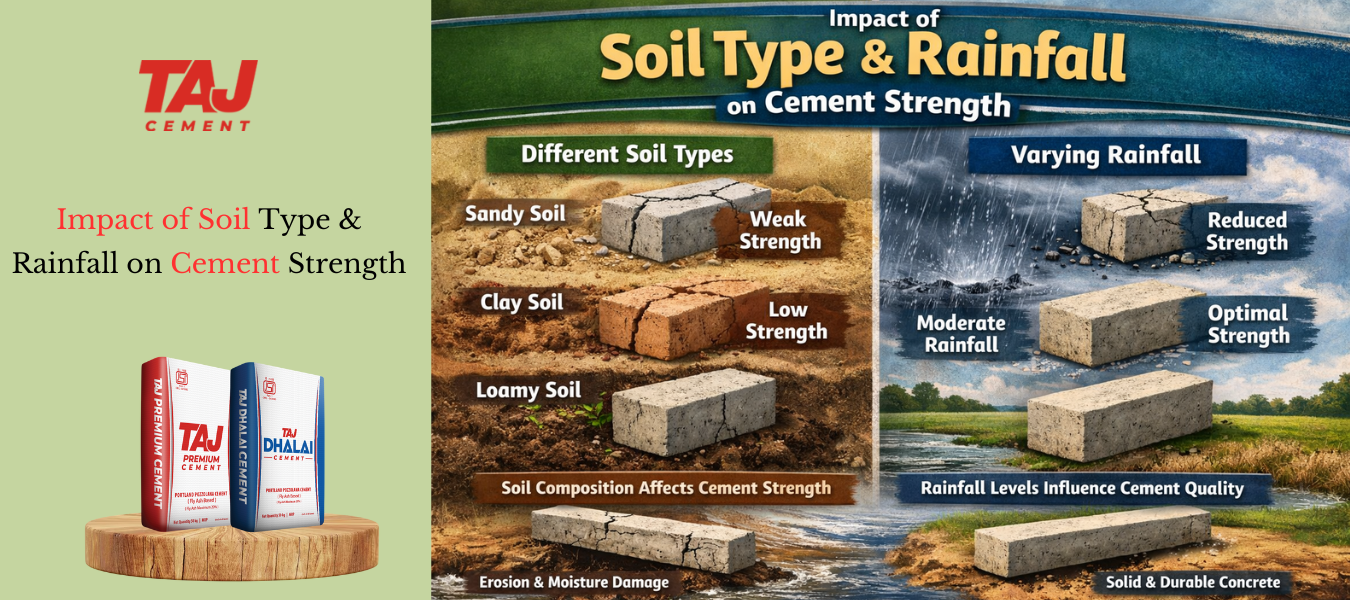

How Different Soil Types Create Complications in Gaining Cement Strength

The quality of the soil can also affect the cement strength. When applying cement, the construction material also reacts with soil and forms calcium silicate hydrates (C-S-H). This rock-like material (soil cement) adds strength to the entire structure.

In regions with heavy rainfall, including Assam or Meghalaya, many sites sit on soft, water-logged soils such as clay, peat, or organic deposits, especially in low-lying valleys and hill bases. These soils already hold a large amount of moisture, which changes how cement behaves.

For instance, when workers mix cement into soft soil, they need the right balance of soil particles, water, and compaction to gain strength:

- In the first stage, the soil remains weak because there is not enough cement to bind the particles.

- In the middle stage, cement starts bonding to the soil, improving strength and stability.

- In the final stage, the soil becomes properly solidified and can support loads.

But if the soil is too wet or poorly structured, it prevents proper bonding. As a matter of fact, during compaction, the forming cement bonds can break instead of strengthening. This means that even if masons add more cement, the soil may still fail to perform as expected.

Understanding Taj Cement Types and How They Behave

Different cement grades respond differently to moisture, curing time, and load demands. Taj Cement offers a wide range of cements for construction, including:

Taj OPC 43 Grade Cement

OPC 43 is a common choice in residential construction. Since it gains strength at a steady pace, it is used in columns, beams, and slabs with proper curing. The cement produces less heat of hydration and has a lower risk of shrinkage cracks.

Taj OPC 53 Grade Cement

OPC 53 gains early strength fast. During the monsoon, it can be beneficial. But the cement is sensitive to excess water and needs controlled curing. It’s a perfect choice for a time-bound process.

Taj Premium Cement (Blended Cement)

It is a premium blended cement containing supplementary materials. This improves the workability and durability of the cement. It offers better resistance to moisture ingress, making it a perfect choice for foundations in damp soil, plaster and places that are often exposed to moisture.

Ta Dhalai Cement

Dhalai cement is commonly used for roof slabs and mass concreting. It handles volume pours well.

Wrap up

In regions like Meghalaya, where rainfall is almost a daily occurrence, cement performance relies on grade selection, water control, and curing discipline. Contractors and homeowners also need to be familiar with soil quality and how it impacts the cement strength. Because at the end of the day, the difference between a long-lasting structure and a problem-prone one often lies in small decisions you make when choosing cement for a monsoon climate.

FAQs

1. Does rain affect cement?

Yes. Rain can increase excess water. It also disrupts hydration, lowers concrete strength. This can raise long-term risks like cracks and seepage.

2. What is the 20/30/40 rule in concrete?

It refers to strength grades (MPa), indicating how much load concrete can safely carry after proper curing.

3. Will cement dry if there is too much water?

It may sit on the surface, but excess water weakens internal bonding and reduces long-term strength.

4. What is soil cement?

Soil cement is soil mixed with cement and water, forming a hardened, rock-like layer after proper compaction.

5. What does cement do to soil?

Cement binds soil particles together, reduces moisture sensitivity, and improves strength and load-bearing capacity.

6. Can you mix cement with soil?

Yes, but only with proper moisture control, correct cement content, and adequate compaction to achieve strength.

7. Can I put cement over soil?

Yes, but the soil must be compacted, stable, and properly prepared to prevent cracking and settlement later.

Leave a Reply