11 Feb 2026

If you’re in the construction line or getting ready to build your own house, you’ve probably noticed how cement prices keep fluctuating. Some days they sit higher than usual, other days they dip without warning. Since cement isn’t something you can swap out or skip in a project, these changes matter. You need cement in bulk for construction projects. So, when the rate drops even by a few rupees, you end up saving a good amount in the long run. But what really pushes the price up or drags it down?

Let’s take a closer look:

What Impacts the Cost of Cement for Home and Commercial Projects

There are quite a few things that influence cement price:

1. Price of Raw Materials

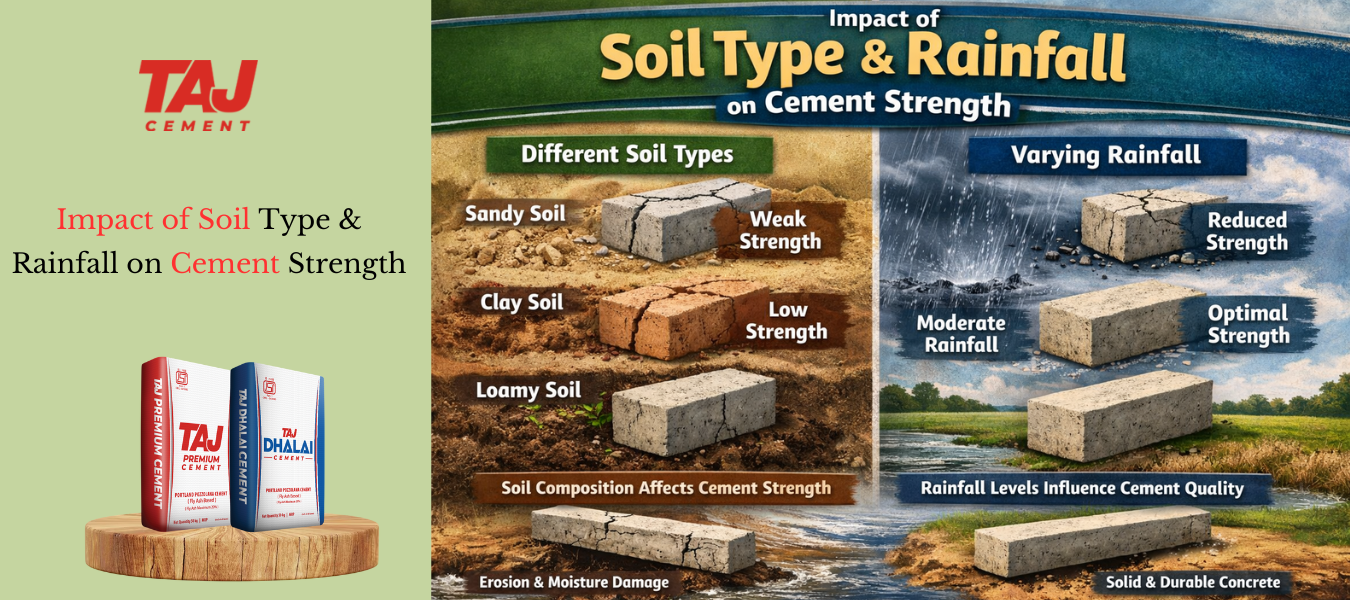

Cement is manufactured using various materials like limestone, clay, gypsum, fly ash, and clinker. When the cost of these materials rises, the final price naturally goes upward.

The price of raw materials usually increases due to these factors:

- Mining restrictions on limestone.

- Importing gypsum can be expensive.

- Higher cost of fly ash transportation.

- During peak seasons, clinker supply increases.

2. Energy & Power Costs

Did you know that 30–40% of the production cost for cement manufacturing is due to fuel and energy? Since the Kilns run at extremely high temperatures, and grinding units need constant electricity, the process consumes a massive amount of energy.

The manufacturing cost increases with:

- Rising coal or petcoke prices

- Electricity tariff changes

- Global fuel market volatility

3. Transportation & Logistics

Cement is bulky and heavy. The farther it travels from the factory, the more it costs.

Transportation cost depends on:

- Diesel prices

- Road and rail availability

- Region-to-region freight variation

- Last-mile delivery charges

This is why the same cement brand may cost more in one state and less in another.

4. Demand–Supply Balance in Construction Seasons

Construction projects usually slow down or pause during the peak monsoon season. In Northeast India, the workable construction window is even shorter because heavy rainfall, rough terrain, and logistical challenges slow down progress even more. The post-monsoon dry season, roughly from October/November to March, becomes the peak construction period. Naturally, cement demand rises during this time. But higher demand and limited supply often push cement prices upward.

5. Government Policies & Taxes

Government rules and policies also cause a sharp change in the cement price, such as:

- Mining laws,

- Strict environmental norms,

- New compliance requirements

- Taxes

These causes manufacturers often spend more on sourcing materials and upgrading equipment. These added costs eventually show up in the final price of a cement bag. So, it is better to look at the government policies.

6. Brand & Product Type

Cement is available in different types and grades, which can affect the price of cement. But you might have noticed that the price for the same grade of cement is different. It’s because premium brands with stronger market trust often charge slightly more.

Here’s usually how the price varies:

- OPC 43 / 53 Grade – usually pricier

- PPC – stable and cost-effective

- PSC – coastal protection, sometimes higher in price

- Specialty cement – Generally costly than general purpose cement.

7. Transportation Infrastructure

Transportation costs can heavily influence the price of cement, especially for northeastern states in India. The rough terrain and changing climate can add up to the final cost. Compared to that, regions with better connectivity usually enjoy more stable prices.

8. Competition in the Market

Market monopoly is another factor that buyers often have to keep in mind. If a place has several factories, then the prices tend to remain steady. But in areas with fewer manufacturers, prices can be higher because supply is controlled by a small group. This also influences:

- Discounts,

- Dealer margins, and

- Bulk-purchase benefits.

9. Packaging & Handling

Cement reacts when it comes in contact with water and starts forming tiny lumps inside the bag. Though it may not seem like a major deal, this weakens the binding strength of the cement. It doesn’t set properly when mixed with water at the site, and also leads to weak concrete and cracks. So, manufacturers need to pay extra attention when packaging, bag quality, and handling. Besides the storage cost, dealer meringue also increases the cement price per bag.

How Can Buyers Use This Information

If you are a buyer planning for an upcoming project, knowing what factors can help you save up on your cement expense. For example:

Purchase in Bulk

When buying, try to purchase in bulk. This way, you can reduce freight and dealer margins.

Look into policy change

Check if there is any tax exemption on the cement price. For example, under the revised GST regime launched in September 2025, tax on most cement types has dropped from 28% to 18%, making it an ideal time to stock up.

Avoid buying during the high-demand season

Try to avoid purchasing during the peak season. It will help you to avoid paying extra for the sudden price spikes and maintain your construction budget.

Compare Brands

Always compare brands. Even though price is a major decision factor, a construction project is expected to last decades. So, how the cement performs is important.

Know the Cement grade

Consider whether the cement you are purchasing is ideal for your project and environment. For states like Meghalaya or Assam, with high humidity, it is better to go for a cement with superior long-term durability and resistance. You don’t have to use the same type of cement for every project.

PPC cement is an excellent choice for foundations, footings, and other underground structures. OPC 53 Grade cement, on the other hand, is preferred for reinforced concrete (RCC) structures like beams, columns, and slabs.

Go for local manufacturers

Since transportation can eat up your budget, check plant availability and distance. Choosing a local manufacturer like Taj Cement might be a wise decision for cities like Guwahati and Shillong. We have a great supply network and deliver high quality cement that meets the market standards.

Final Thoughts

Cement is an essential construction material. Therefore, you need a separate budget for it. Cement prices usually change due to raw materials, energy costs, logistics, regulations, local competition, and seasonal demand. When you know the factors, you can plan better and cut down the expense to a certain extent.

FAQs

1. What factors influence cement prices?

Cement prices mainly change due to various factors, such as: Cost of raw materials, Fuel and energy charges, Transportation distance, Construction season demand, Government policies, Brand type, Market competition, Packaging quality, and Dealer margins.

2. Are cement prices rising?

Cement prices tend to move up and down based on demand and market conditions. Prices also go up during peak construction seasons like October–March, especially in regions where supply is tight. But, the recent tax changes have reduced the cement price considerably.

3. Do the costs of cement for home and commercial projects vary?

Yes, the cost often varies. Commercial projects usually purchase cement in bulk, which helps them get lower per-bag rates, reduced freight, and better dealer discounts. They may also have long-term contracts that protect them from monthly price fluctuations. Home builders buy smaller quantities, so they typically pay the standard retail price, which changes with market conditions, brand, and location.

4. What is the cost of 1 kg of cement?

Cement is usually sold in 50 kg bags, so the per-kg price depends on the bag rate in your region. For example, if a 50 kg bag costs ₹400, then 1 kg would cost around ₹8. Since prices vary by state, brand, and season, checking with a local retailer gives the most accurate rate.

5. Which type of cement is cheapest?

Among commonly used cement types, PPC (Portland Pozzolana Cement) is usually the most cost-effective. It offers good durability, performs well in humid regions like the Northeast, and costs less than OPC 43 or OPC 53 Grade. PSC may be slightly higher depending on location, and specialty cement is generally the most expensive.

6. What is the Taj Cement Price?

Taj Cement price usually vary depending on the grade you choose. You can contact us directly to know more about deals and dealership information.