11 Feb 2026

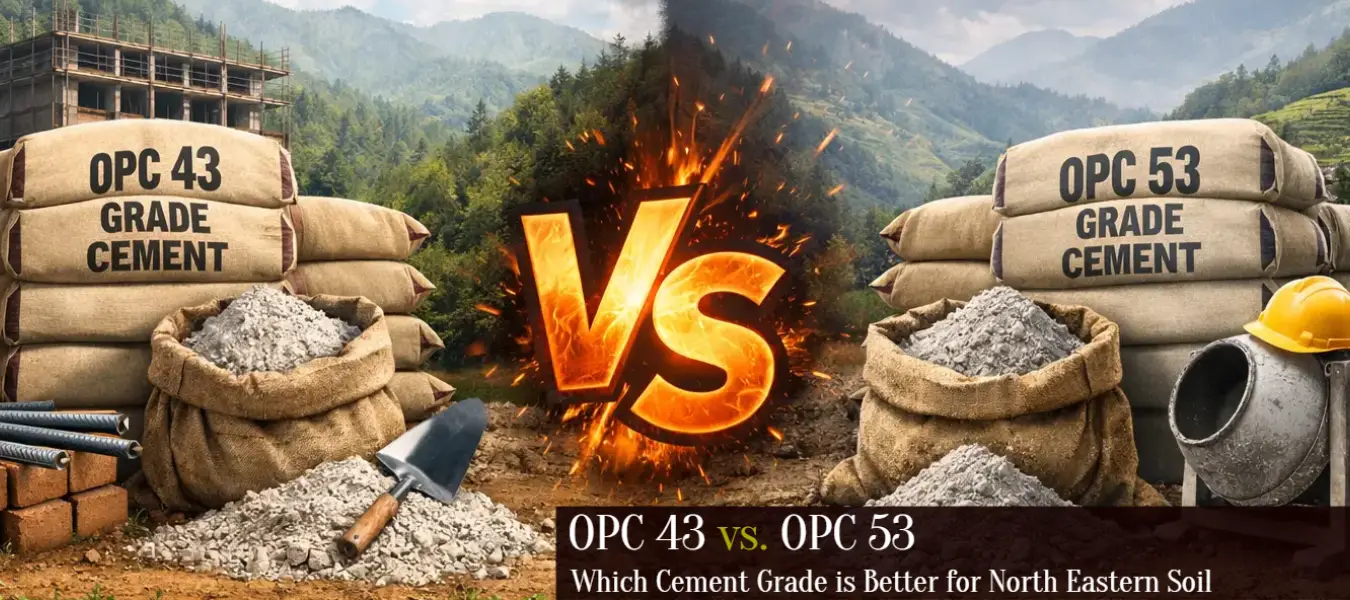

Cement grades are available in different types. Depending on the region, application, and environment, which grade of cement you need for your construction projects varies. In North North-Eastern states of India, construction challenges go on and on. The land shifts from alluvial plains to hilly terrain within a few kilometres. Most states fall under Seismic Zone IV or V. And with heavy monsoons, drench sites, recurring landslides, and waterlogging, choosing the right cement becomes essential to increase the durability and longevity of a building.

Ordinary Portland Cement (OPC) is widely used for residential and commercial projects in states like Manipur, Assam and Meghalaya. This cement comes in different grades, including OPC 33 grade, OPC 43 grade, and OPC 53 grade.

In this article, we will be discussing how OPC 43 and 53 performs in north-east India, and whether one is better than the other:

Understanding OPC 43 Grade and OPC 53 Grade

Before we compare the two cements, let’s first understand what the “grade” signifies. A cement grade expresses the 28-day compressive strength, which basically means how much weight or pressure the concrete can handle before it gets crushed in mega pascals (MPa). The grade is also an indication of how fast the cementation gains strength gain, risk of thermal cracking, fineness, and long-term durability.

Under Indian norms (IS 269:2015), both OPC 43 and OPC 53 must clear identical chemical and physical quality tests. So, when it comes to choosing between them, it is not a matter of certification, but selection as per structural needs.

What is OPC 43 Grade Cement?

OPC 43 is a type of Ordinary Portland Cement that develops a compressive strength of 43 MPa after 28 days of proper curing.

What is OPC 53 Grade Cement?

OPC 53 is a higher-strength variant of Ordinary Portland Cement that reaches 53 MPa after 28 days of curing.

Performance and Behavioural Traits of OPC 43 Grade vs OPC 53 Grade

OPC 43 and OPC 53 perform differently when used in different environments, for instance

Strength Development

When cement is used to make concrete, it becomes strong through a process called curing. In this process, you have to keep the concrete moist so it can become strong. Concretes usually gain most of their strength within the first 28 days.

For OPC 53 cement, it reacts faster and gains strength much faster in the first 3-7 days than OPC 43. This means, if you are on a tight construction schedule, OPC 53 will provide more strength in a short period of time.

OPC 43, by contrast, develops strength steadily. It provides enough working time for proper placement and compaction. Even after 28 days, OPC 43 continues to gain strength and offers more than adequate final strength for most home-building requirements.

Here’s a small table on the strength difference between OPC 43 and 53 grade after 3, 7, and 28 days

| Age of Concrete | OPC 43 Grade Cement | OPC 53 Grade Cement |

| 3 Days | 23 N/mm² | 27 N/mm² |

| 7 Days | 33 N/mm² | 37 N/mm² |

| 28 Days | 43 N/mm² | 53 N/mm² |

Fineness & Workability

When manufacturing, OPC 53 is ground finer. This makes concrete mixes denser and more workable. For regions with water-logged soil, this is highly suitable as denser concrete reduces moisture from penetrating.

In clay soils, compaction takes longer. So, a slower-setting cement like OPC 43 gives workers more time to place and level the concrete. This reduces the chances of cold joints, especially in small residential projects.

To sum it up:

| Aspect | OPC 43 Grade | OPC 53 Grade |

| Fineness | Moderately ground | Ground finer |

| Workability | Slower-setting mix gives workers more time to place, level, and compact | Finer particles create smoother, more workable concrete |

| Best Soil Type | Clayey soil where compaction takes longer | Water-logged or moisture-prone soil needing denser, tighter concrete |

| Construction Advantage | Reduces the risk of cold joints in small residential projects | Produces denser concrete that resists moisture penetration |

Heat of Hydration

Even though concrete needs moisture, it needs to be controlled. While moderate humidity reduces the chance of cracking, too much slows evaporation. Sudden rain, on the other hand, can damage the concrete, especially if it is fresh or moderately cured (less than 24 hours to 3 days).

OPC 53 tends to hydrate rapidly, producing more heat. The cement grade requires proper methods, such as wet burlap, polymer membranes, or frequent water sprinkling, to stay stable. This can be complicated in humid, rainy climates. When the surface cools too quickly or curing is inconsistent, it can lead to micro-cracks, especially in large slabs, thick footings, and retaining walls.

OPC 43 gains strength more slowly, which is actually more suitable for humid and rainy climates. Since it doesn’t produce high heat unlike OPC 53 grade, the concrete stays cooler and reduces the risk of sudden temperature shocks when rain falls.

Here’s how OPC 43 and OPC 53 behave in humid climates, at a glance:

| Aspect | OPC 43 Grade | OPC 53 Grade |

| Hydration Speed | Slower and more predictable | Faster hydration |

| Heat Produced | Lower heat, so low risks of thermal cracks | Higher heat, higher crack risk if curing is poor |

| Behavior in Rainy/Humid Climate | Performs reliably during sudden rain. suitable for large pours | Needs strict curing. Sudden cooling can cause micro-cracks |

Application in Construction

OPC 43 and OPC 53 are both widely used in construction, but they serve different purposes based on the strength required, the load a structure must carry, and how quickly the concrete needs to gain strength.

OPC 43 is commonly used in general construction work where moderate strength is sufficient. It gains strength at a steady pace, making it suitable for residential slabs, brickwork, plastering, flooring, and compound walls.

OPC 53, on the other hand, is used for structural elements that must carry heavy loads and need higher strength. It gains strength faster and reaches a higher final strength, making it ideal for RCC columns, beams, foundations, bridges, high-rise buildings, and other load-bearing components.

Let’s take a look at the application of these two cement grades:

| Application Area | OPC 43 Grade Cement | OPC 53 Grade Cement |

| General Construction | Ideal for residential slabs, brickwork, plastering, and flooring | Suitable for stronger slabs and faster project timelines |

| Structural RCC Work | Used for light to moderate load RCC | Preferred for high-load RCC (columns, beams, slabs) |

| Foundations | Suitable for small residential foundations | Recommended for deep or high-load foundations |

| High-Rise & Commercial Buildings | Not usually preferred for multi-storey structures | Standard choice for multi-storey and commercial construction |

| Infrastructure Projects | Used in small-scale or non-critical elements | Widely used in bridges, flyovers, industrial floors |

| Large Concrete Pours | Good for plinth beams, ground floors, compound walls, retaining walls | Can be used but requires very strict curing due to high heat |

| Time-Sensitive Projects | Not preferred when quick strength is needed | Best suited due to fast early-strength gain |

Choosing between OPC 43 Vs OPC 53 in NE Climate & Soil Condition

Most North East states, including Assam, Meghalaya, Mizoram and Manipur, deal with changing soils, long monsoons, humidity and seismic risk all year round. All these factors impact concrete curing, load distribution, and might lead to cracks. So, you need to choose the right cement grade:

In Regions With High Rainfall & Humidity

If your region usually has a long monsoon, then OPC 43 might offer better performance. Since its hydration process is slower, it is less sensitive to rain and sudden temperature changes. When using OPC 53, it needs stricter curing during rainfall to avoid micro-cracks, especially in large slabs or exposed concrete.

Places with High Seismic Activity

The North East lies in high seismic zones. So, it is better to use OPC 53 for load-bearing RCC elements like columns, beams, and shear walls. It has a higher strength and helps buildings withstand earthquake forces more effectively. OPC 43 can be used for non-structural parts that do not contribute to earthquake resistance.

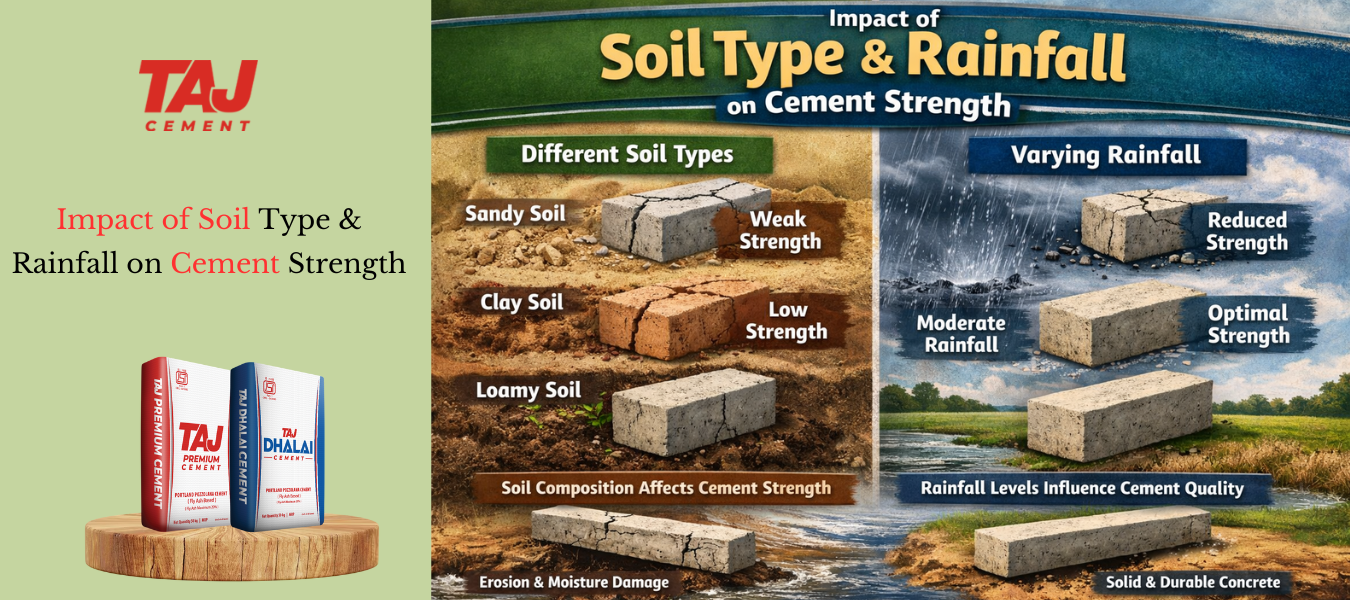

Based on Soil Type

You should understand the soil type of your region before picking an OPC cement grade. For instance:

- Soft alluvial or water-logged soil: OPC 53 works better due to its higher final strength and dense concrete formation.

- Clayey or moderately compactable soil: OPC 43 offers better workability and longer setting time, making it easier to place and finish.

- Hilly or slope-prone soil: OPC 53 is preferred for retaining structures and deep foundations.

To sum it up

Whether OPC 43 grade is better or OPC 53 grade is better depends on your application and the environment. What performs better in one condition might not do well when the environment changes. So, before you make any decision, consult with a professional before making a decision. At Taj Cement, we deliver both OPC 43 and OPC 53 grades that comply with the BIS standard.

FAQs

Is OPC 53 cement waterproof?

No. OPC 53 is not waterproof by itself. Concrete becomes water-resistant only when mixed properly and cured well. For waterproofing, it requires additives or coatings.

Which is better, OPC or PPC?

PPC offers better long-term durability and crack resistance, while OPC gains strength faster. The choice depends on project type, climate, and structural needs.

What do 33, 43, and 53 grades of cement mean?

These numbers show the cement’s 28-day compressive strength in MPa. Higher grades means higher strength after curing.

Is OPC cement good for house construction?

Yes. OPC works well for RCC, slabs, beams, and structural components, especially when faster early strength is needed.

Which grade of cement is best for house construction?

OPC 53 is preferred for RCC and structural work. OPC 43 suits masonry, plastering, and general residential needs.

Why is 53-grade cement not used?

OPC 53 grade cement is used in many projects. But sometimes avoided because its fast hydration increases cracking risk without proper curing, especially in large pours or highly humid climates.