11 Feb 2026

Roofs protect buildings from rain, sun, and wind. They take the first hit from the weather every day. That’s why durability becomes a critical factor in long-term performance. Cement is one of the most crucial components in roof and RCC slab construction. Choosing the right one helps cut future repair bills.

For areas with heavy downpours, humidity, and prolonged monsoons, this becomes even more important. Especially in North-East India, homeowners frequently have to worry about leakage, structural cracking and concrete spalling.

In this article, we will discuss how you can pick the best cement for roofs. We will also guide you with practices to stop seepage before it starts and prevent long-term headaches:

What is Roofing and RCC Slabbing?

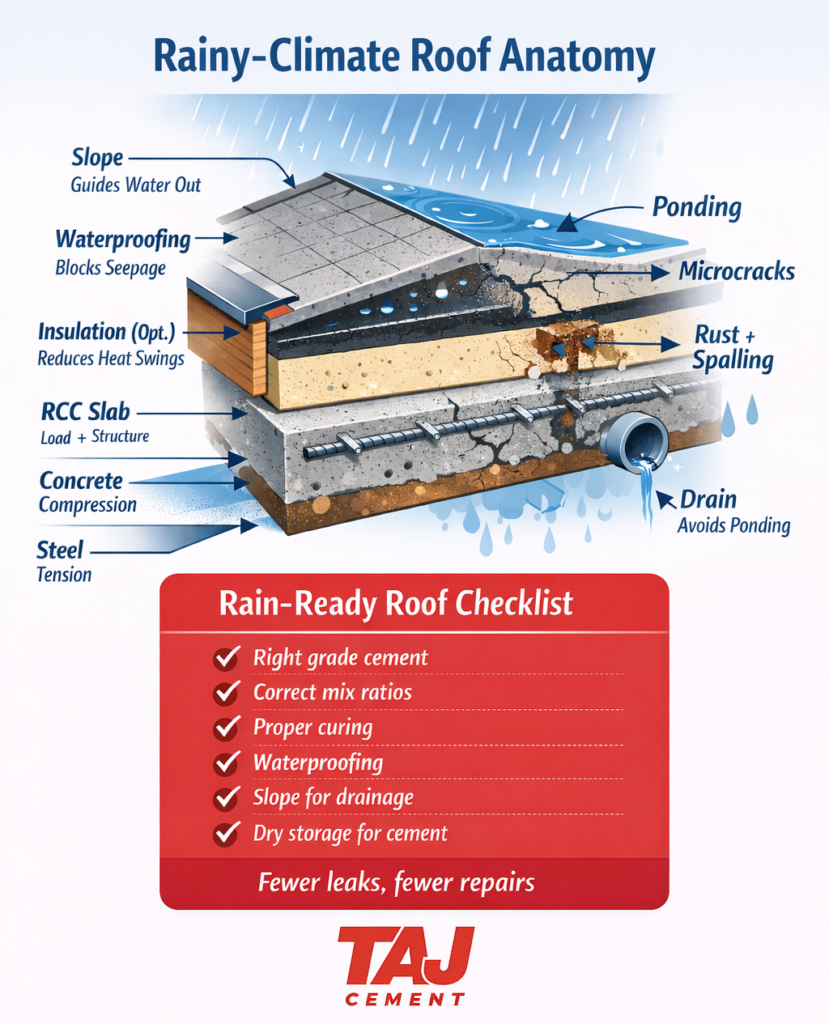

Roofs shed water and protect interiors from dampness and leaks. In wet and humid regions, roofing functions as a system with interconnected components:

- Slope for drainage,

- Waterproof membranes for moisture control, and

- Flashing to seal vulnerable areas, such as edges, joints, and pipe penetrations.

RCC slabs are made of concrete with steel inside. The concrete withstands the heavy weight (compression) of the slab itself, along with flooring, waterproofing, and other permanent layers. Steel, on the other hand, resists tension. Therefore, the slab can bend and move without cracking, a behaviour that becomes crucial during earthquakes.

The slabbing process starts with a mix of cement, sand, stone, and water. The mix is then poured into formwork and left to set and harden. Here, masons must maintain the ratio as it can affect strength and durability.

During setting, builders need to control temperature and moisture, as too much water in the mix can reduce strength. However, in North-East India, where sudden rain and humidity make construction unpredictable, this becomes tricky. That’s why choosing the best cement that performs well in wet and humid weather helps the slab gain strength properly and avoid future issues.

Why Roof and RCC Quality Is So Important

When it comes to building a house, homeowners focus on the interior, like fittings, tiles, and paint. While these elements make the home look more appealing, the roofing and RCC slab are the real backbone of the building.

If the roof or slabs are weak, almost every room in the house eventually shows signs of damage. In rainy and humid climates, roof damage is more frequent. You will see damp walls or cracks starting to appear. Stains, mould, or peeling plaster become constant, no matter how much you repair and maintain. Thus, considering the best cement and other construction materials isn’t just about luxury, but about basic safety and long-term savings.

Safety

Spalling is a common occurrence in regions with a long monsoon. This occurs when moisture enters steel reinforcement, leading to corrosion. Rust expands the steel, cracks the concrete, and weakens the entire system. This raises safety concerns for people residing inside the building. Choosing the right grade of cement can avoid this to a certain extent.

Load Performance

Roofs and RCC slabs carry two types of loads:

- Dead loads: This includes the slab itself along with flooring, waterproofing layers, and other permanent materials.

- Live loads: This includes people walking on the terrace, furniture, water tanks, and sometimes even temporary storage during construction.

Besides, roofs and RCC slabs also have to endure sun exposure, wind pressure, and rainfall. If the slab is poorly cast or constructed using the wrong grade of cement, buildings start to slowly lose strength.

Repair Costs and Disruption

Roof and slab repairs are not just expensive but also inconvenient. The process involves:

- Hacking plaster,

- Replacing waterproof layers,

- Sealing joints, repainting ceilings, and

- Repairing reinforcement (sometimes).

You also have to move furniture in and out and apply fresh paint. But, since the foundation is poor, there is no real solution. You have to patch after almost every monsoon. If you leave it as it is, moulds start to grow, making rooms uninhabitable.

That is why choosing the right cement and the correct mix is important during construction. Along with this, proper waterproofing cuts down repeat repairs and keeps the house healthier for years.

What to Look for in Cement for Rainy & Humid Climates

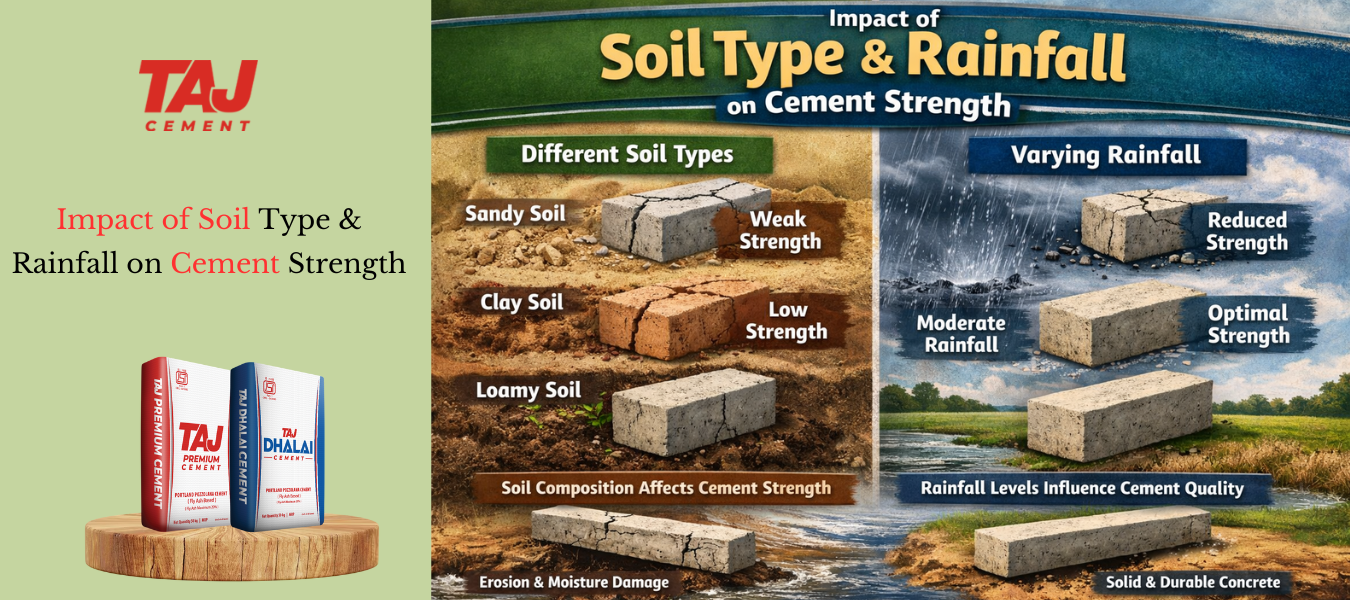

When choosing cement for construction projects for rainy and humid climates like Assam and Meghalaya, here are a few facts you need to know:

Moisture Resistance and Low Permeability

A good cement should create concrete with low permeability. This means less water travels through the slab. Lower permeability protects steel from chlorides, sulphates, and constant wetness.

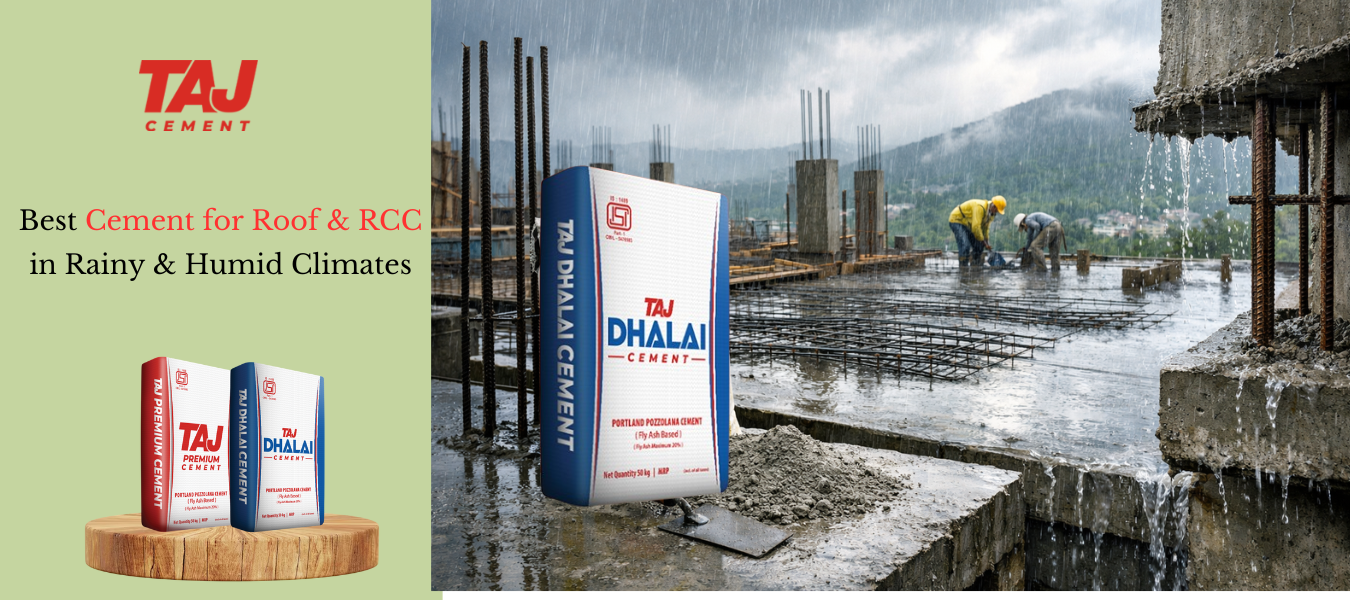

Reliable Early Strength and Consistent Gain

Concrete usually cures 85-90% within the first 28 days. While the time-span may seem short, it is concerning in north eastern states where rainfall is frequent. Cements like Taj Dhalai and Taj Premium are manufactured to suit such an environment and allow faster strength gain.

Workability and Compatibility with Admixtures

Extra water can weaken concrete. Thus, the best cement to use in such rainy and humid weather is the one that works well with water-reducing admixtures.

Packaging and On-Site Storage

Cement packaging in a humid environment should be done properly. Cements react with water and can form lumps. Even the best cement becomes weak if it absorbs moisture inside the bag. That is why Taj Cements come in tamper-proof, high-strength BOPP laminated packaging.

Common Roof & RCC Problems in High-Rainfall Areas

When it comes to construction, there are quite a few problems contractors have to deal with:

Slower Setting and Curing Issues

Concrete goes through hydration. But the rainy or humid weather can slow down the process. Besides, if rainwater mixes with fresh concrete, the cement paste becomes diluted. This results in weak zones, uneven surfaces, and poor bonding with steel.

Seepage and Mould

When roofs stay wet for long periods, they become the ideal place for mould to grow. The mould causes a musty smell inside the home. The inside feels more humid and uncomfortable. Plus, it can also cause small cracks and pores, which later lead to leakage. This is the main reason why houses in heavy rainfall regions are constructed with sloped roofs instead of flat roofs.

Thermal Stress

For states like Assam and Meghalaya, thermal movement is quite frequent. The slab heats up during the day and cools down at night. As the cycles continue, microcracks start to widen. Once water enters these cracks, it reaches the steel bars and rust starts to form, affecting the building’s integrity.

Hairline Cracks After Monsoon

Hairline cracks appear on the roof walls. While these cracks look harmless, they act like small channels if left unattended. When the monsoon returns, water enters through them and moves deeper.

Damp Ceilings and Peeling Finishes

When waterproofing layers fail or flashing gaps open, ceilings become damp. Stains appear, plaster detaches, and sometimes chunks of plaster fall off. Painted ceilings absorb moisture and bubble.

Weak Slab Edges and Corner Failure

Edges and corners receive less compaction and are more exposed to rain during construction. If the concrete cover over the steel is thin, these areas weaken first. Over time, corners chip away.

The Bottom Line

Roof and RCC slabs add structural integrity. Therefore, it is important to choose the best quality raw materials during construction. However, even the best cement might not work well if you don’t consider workability, early strength gain, and moisture resistance. Our Taj Dhalai and Taj Premium cements are tailored for rainy and humid environments. The cements support long service life, reduce repairs, and keep homes safer through every monsoon.

FAQs

1. What is the purpose of an RCC slab?

An RCC slab carries building loads, resists bending, and protects interiors. The concrete handles compression while steel manages tension and offers durable structural support for roofs and floors.

2. Which cement is best for roofing?

For rainy and humid regions, use cement that offers early strength gain, low permeability, and better moisture resistance. Taj Dhalai and Taj Premium are suitable choices for such climates.

3. Will roof cement stop leaks?

Roof cement helps reduce seepage. But it alone cannot guarantee leak-proof performance. Proper waterproofing, correct mix ratios, and good construction practices must also work together to prevent leakage.

4. What is roof cement?

Roof cement refers to cement used in RCC slab construction for roofs. It forms part of the structural system that sheds water, protects interiors, and resists rain, heat, and wind exposure.

5. Is M20 or M25 better for roofing?

M25 generally performs better for roofing due to higher strength and durability, especially under heavy loads and rainy climates. However, it usually depends on design requirements and engineering specifications.