11 Feb 2026

Summary: A clear comparison of AAC blocks vs traditional bricks for Northeast India homes. We have explained climate impact, safety, insulation, foundation load, and why AAC suits Assam conditions better.

Construction projects like building a house in North-eastern states is complicated, heavy rainfall, high humidity, soft soils in many pockets. Not just that, landslide-prone slopes and earthquake sensitivity make it essential to choose the right construction materials. In the past, traditional clay bricks were mostly used for house construction. But now AAC (Autoclaved Aerated Concrete) blocks are slowly gaining popularity in states like Assam and Meghalaya.

Homeowners now compare AAC blocks vs traditional bricks to make the right decision. And cost can’t and shouldn’t be the only decisive factor here. You also need to account for climate, safety, comfort, and long-term upkeep.

This guide breaks down AAC blocks vs clay bricks with Assam and Northeast India firmly in focus.

Understanding Clay Bricks and AAC Blocks

Before we explore the properties and benefits, let’s first understand:

What are Red / Clay Bricks?

Red or clay bricks are made from natural clay and shale. Sometimes manufacturers mix sand or lime as well. The raw materials are moulded into shape, air-dried, and then fired in kilns at very high temperatures. This firing gives them the red colour, hardens the bricks, and gives them strength.

What are AAC (Autoclaved Aerated Concrete) Blocks

In AAC blocks manufacturing, the raw materials usually are cement, lime, sand or fly ash, water, and a small amount of aluminium powder. The blocks are cured in high-pressure steam autoclaves, which keeps them lightweight while also adding strength.

AAC Blocks vs Traditional Bricks: A Quick Comparison

Let’s take a look at how these two construction materials differ in terms of:

Weight

AAC blocks are usually 3-4 times lighter than clay bricks. Taj AAC blocks are engineered to be 80% lighter than red bricks. This reduces dead load and structural stress on the building significantly. Since the blocks are lighter, they respond better during earthquakes, making them safer in seismic or hilly regions.

Compressive Strength

Even though AAC blocks are lightweight, they offer good compressive strength. They deliver predictable load performance when integrated with RCC frames.

Size & Uniformity

AAC blocks usually come in a consistent size and smooth edges as they are factory-cut to precise dimensions. Hence, the walls are neater. Traditional bricks, on the other hand, might slightly vary in size, which means they need on-site adjustments.

Thermal Performance

AAC blocks have millions of air pockets, which transfer heat slowly. So, the inside of the building stays cooler in hot climates and warmer in cooler seasons. Clay bricks, on the other hand, are denser. They absorb heat during the day and release it slowly.

How Assam’s Climate Influences AAC Block & Bricks Performance

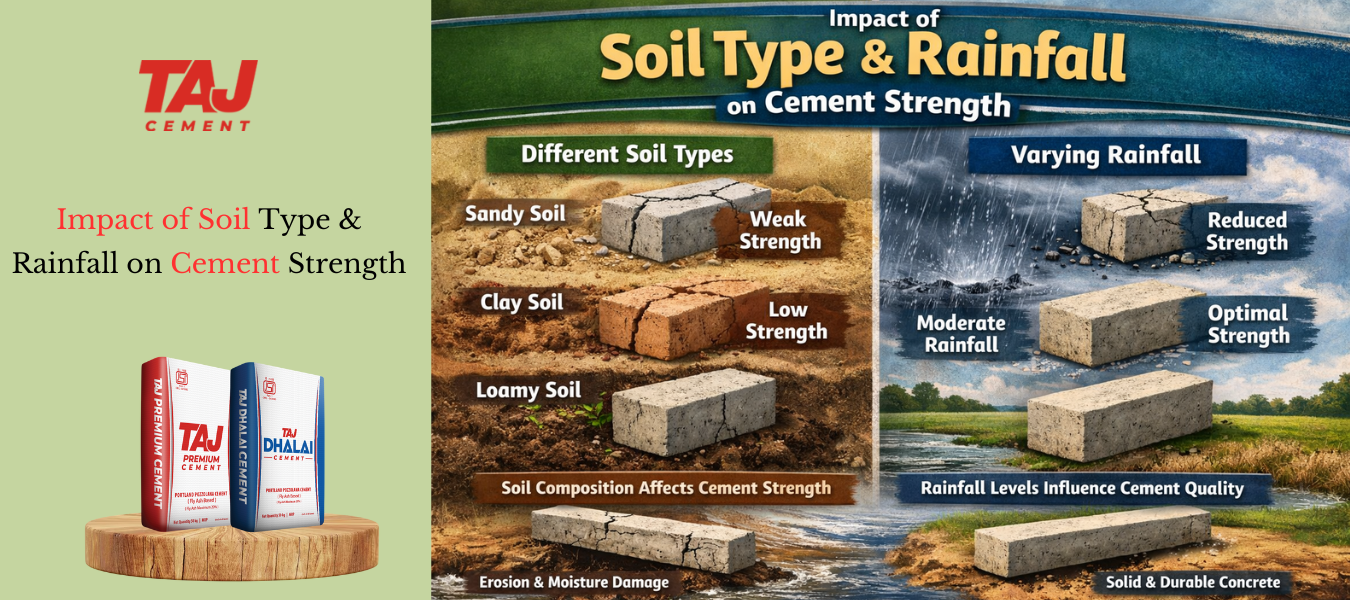

Materials that work well in dry or moderate climates may struggle in the northeastern environment. Here is a comparison of how the two materials perform:

Moisture and water absorption of Clay Bricks vs AAC Blocks

Traditional clay bricks have several tiny holes or pores that absorb water easily. So, during the months-long monsoon with constant rain in Assam and the neighbouring states, it can lead to damp patches on internal walls. Over time, salts move to the surface, causing efflorescence. The layer of plaster starts to deteriorate faster, and also increases the chance of seepage.

AAC blocks are also porous. But their internal structure behaves differently. Instead of concentrating the moisture into a single place, the air pockets spread evenly. Hence, walls dry faster once the external moisture level drops.

When using AAC blocks, it is important to be sure that exterior plastering and waterproof coatings are done properly.

AAC Blocks vs Clay Bricks: Thermal Insulation

Aside from the high humidity, the heat fluctuation is also common in north east India. Red bricks usually store heat during the day and release it slowly into interiors. This basically means that the inside temperature rises in the summer and decreases during winter.

AAC blocks trap air within their structure. This slows down heat transfer. Therefore, the interiors stay cooler (2–3°C lower than clay bricks) during the day and more stable overall.

Bricks vs AAC Blocks: Earthquake Resistance

Most North-Eastern states, including Assam and Meghalaya, fall within high seismic zones. So, how the bricks behave can impact safety concerns.

Red brick walls are heavy. When the ground starts to shake, this mass generates higher inertial forces. As a result, there is high stress on columns, beams, foundations, and masonry joints. If the reinforcement is not adequate, it leads to cracks even when the tremors are minor.

AAC blocks weigh less. Hence, the earthquake-induced forces acting on the structure are also low. But you need to integrate them with RCC frames, horizontal and vertical bands, and anchored correctly to columns and slabs.

Landslides, Slopes, and Foundation Stress

When you’re building a house in sloppy terrain, you have to consider landslides and foundation stress. When the wall system is too heavy, it increases the load on the foundation. Which means you will need deeper or wider footings. This can increase the construction cost.

AAC masonry significantly reduces wall weight. So, foundation stress is lower. Contractors have more flexibility in structural planning, which is especially valuable for hillside homes.

AAC Blocks vs Red Bricks Cost in Assam

Budget is always a concerning factor for many homeowners. And if you consider the upfront material cost, clay bricks are less expensive than AAC blocks. But a house is a long-term investment, so you need to consider the overall build cost.

In AAC construction, your contractor will need less mortar, have faster labour cycles, and thinner plaster layers. However, transportation costs and local availability often play a major factor in the final budget. At TAJ Cement, we have dealers spread across Assam and Meghalaya.

The Role of Execution, Labour, and Maintenance in Material Performance

Aside from the environmental factors, there are also other factors that can affect the performance of bricks and AAC blocks, such as:

Construction Speed and Labour

For many construction companies, workers are more familiar and comfortable with bricks. However, clay bricks are heavy and come in smaller units. This means they have to handle more pieces with thicker mortar joints, leading to slower progress each day.

AAC blocks are lightweight, larger and of the same size, which reduces the number of joints and lowers mortar consumption. This speeds up your project speed, a great advantage in areas with frequent rain.

Workmanship

Whether you are installing bricks or AAC blocks, skills matter. For bricks, inconsistent brick sizes, excessive mortar joints, and poor alignment are common problems.

When using AAC blocks, you need to install them properly. In most cases, problems arise due to:

- Using regular cement mortar instead of thin-bed adhesive,

- Poor curing practices,

- Skipping exterior waterproof finishes, or

- Fixing heavy loads incorrectly.

Maintenance and long-term performance

Houses in the north east states are more prone to damage due to constant moisture exposure. For brick walls, this means you have to repaint and plaster frequently due to dampness and cracks. This increases maintenance costs.

But when using AAC blocks properly, they offer more stable plaster performance. Hence, there are fewer thermal cracks and lower repainting frequency. So, in the long-term, maintenance costs reduce.

Final Thoughts

From the above discussion, we can say that AAC blocks are better than traditional clay bricks when it comes to handling, safety, and durability. That doesn’t necessarily mean traditional bricks can’t be used for construction projects. In fact, bricks are still widely used for single-storey buildings and in areas with inconsistent AAC block supply systems. However, for major projects AAC is preferred. And for homeowners thinking long term, switching to AAC block might be a bit more expensive but comes with clear structural advantages.

FAQs

1. Are AAC blocks better than normal bricks?

AAC blocks perform better due to their lighter weight, better thermal insulation, and predictable moisture behaviour. They reduce structural load, handle earthquakes better, and lower long-term maintenance when executed correctly.

2. Which is cheaper, AAC blocks or bricks?

Clay bricks are cheaper upfront. However, AAC blocks often reduce overall construction costs in the long run.

3. Which brand of AAC block is best?

The best AAC block brand is one with consistent quality, proper compressive strength, and reliable local availability. In Assam and Meghalaya, Taj Cement has become popular with our established dealer networks, timely supply and better technical support during construction.

5. Can we apply putty directly on the AAC block?

No, you should not apply putty directly to AAC blocks. You should prepare the surface properly, including applying cement plaster or recommended base coats. This ensures better adhesion, prevents cracking, and improves long-term wall performance.

4. What is the lifespan of an AAC block?

AAC blocks have a lifespan comparable to traditional masonry when installed correctly. With proper waterproofing, plastering, and maintenance, AAC block structures can easily last 50 years or more under Northeast Indian conditions.

6. Are AAC blocks good for heavy rain?

Yes, AAC blocks can perform well in heavy rainfall areas like Assam when proper exterior plastering and waterproofing systems are used.